Automatic

Many different businesses cash in the key cutting machine. It is a handy and versatile thing to possess. Several different types are available today. Here are some reasons to think about these essential cutting tools. There are grooving tools that run parallel with the cylinder. These grooving tools are designed to match up with pins inside the lock. These models are beneficial for many locks. Maybe you would like to let a loved one use the car. They could want their key for the lock. These machines have two holders. One is for the first. The opposite is employed to carry the blank, which can be duplicated. The unit will trace the outline of the first. It will then cut the same precise pattern into the copy.

Semi-Automatic

The semi-automatic is exceptionally almost like the automated method. You have got to observe the machine and inspect the duplicate. This makes sure that it will work. You will get to make adjustments because it duplicates. The automated does everything for you.

Manual

The manual duplicator takes skill and knowledge to use. You will make copies that are single and double-sided. They are going to add door locks for many everyday applications. Hotel and house doors are an example. Automotive uses are another practical purpose. You can work with several blanks on just one occasion, with this unit. It involves more work than other types. This will often cause more mistakes. However, it will depend upon the training and knowledge of the operator. A newbie is more likely to form common errors.

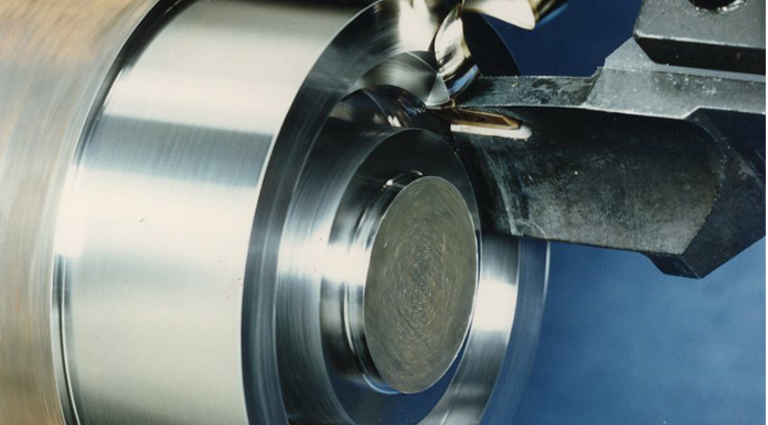

Tube type grooving tools

Tube type or tubular locks require a particular duplication method. The tubular or barrel key features a round cylinder that is hollow. There is also a tab on the tube guide. This makes it easier to show inside the lock mechanism. You would like a particular machine to form these things. You may see tubular locks on vending machines. Alarm systems and individual bicycle locks can also have them. Particular sorts of control panels or security panels may use these locks, too.

Code cutting

Code key cards are duplicated on a code cutting machine — the cardboard is placed within. The machine reads the code on the cardboard. It is a series of grooving tools or notches. The first card is removed, and a blank is installed. The system is them cut onto the blank card.

Punch Code Cutting

This process is remarkably very similar to the code cutter. Code cutting utilizes a rotating wheel. The wheel cuts the code on the cardboard. Punch code cutters use a punch. This is often good for double-sided coding cards.

Different uses

You will enjoy offering an additional service to customers. Essential cutting tools are often a profitable venture for several businesses. You would possibly consider the service for your clients or customers. There are several different kinds to think about. Automatic ones are simple and straightforward to use. Specialty one like tube guide is for specific applications.